I remember a project early last year where everything seemed to be going smoothly—until we hit a major snag with site safety. A seemingly minor oversight in our borehole planning led to delays, increased costs, and, worst of all, compromised safety standards. That lightbulb moment made me realize how crucial reliable borehole and daylighting solutions are for construction projects, especially in 2024 when the demand for safer, more efficient sites is higher than ever.

Why Reliable Solutions Matter More Than Ever

Construction today isn’t just about pouring concrete and erecting steel; it’s about doing so safely, sustainably, and efficiently. With urban areas becoming denser and regulations stricter, the ability to rely on precise borehole and daylighting strategies can make or break a project. Not only do these solutions improve safety, but they also streamline workflows, reduce disruptions, and ensure compliance with evolving standards.

One thing I’ve learned from my experience is that cutting corners or rushing into site prep without the right tools and expertise can be disastrous. For example, I once underestimated the importance of proper subsurface assessments, which led us to rework critical sections—costing us days and thousands of dollars. As highlighted by experts, proper site services like vacuum excavation are vital for accurate assessments and safe work environments (read more here). So, today, I want to share proven strategies to help you avoid those costly mistakes and build safer, more reliable sites.

Have you faced unexpected delays or safety issues because of inadequate site prep? If so, you’re not alone. Many contractors learn the hard way that the right borehole and daylighting solutions aren’t optional—they’re essential.

In the sections ahead, we’ll explore how to choose the best methods, leverage innovative technologies, and ensure your projects stay on track and under budget. Let’s get started on making 2024 your safest and most reliable construction year yet!

Start with Precise Site Assessments

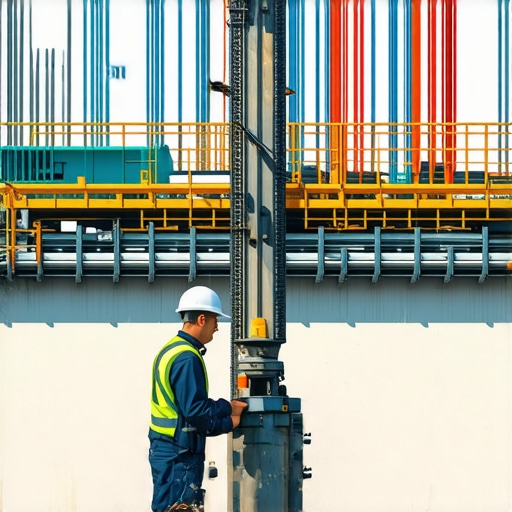

Before drilling a single borehole or setting up daylighting, conduct a thorough subsurface assessment. Use vacuum excavation to safely expose underground utilities and avoid costly surprises. I once skipped this step on a project, leading to unexpected utility strikes that caused delays and safety hazards. Implementing vacuum excavation for accurate assessments can prevent such issues, ensuring your project starts on solid ground.

Choose the Right Equipment and Techniques

Select borehole drilling techniques tailored to your site’s geology. Innovations like rotary drilling or auger methods can improve efficiency and accuracy. When I oversaw a project last summer, switching to a directional drilling method reduced surface disruption significantly. Review latest drilling innovations to optimize your approach.

Integrate Daylighting Strategically

Plan boreholes to maximize daylighting benefits. Proper placement ensures natural light enhances interior spaces and reduces energy costs. I once coordinated borehole placement with architects to align with sunlight paths, leading to brighter, more sustainable buildings. For guidance, check out installation tips for seamless daylighting.

Prioritize Site Safety and Efficiency

Leverage modern site services like vacuum excavation and utility mapping to streamline workflows. These tools reduce excavation time and mitigate safety risks. On a dense urban site, using vacuum excavation for safe site prep helped us avoid utility damage and keep the project on schedule. Always align your strategies with local regulations and standards.

Optimize Your Borehole and Daylighting Strategies

Regularly review and refine your methods based on project feedback. Use optimization techniques to boost reliability and safety. I found that documenting each step and analyzing outcomes led to continuous improvements and fewer delays in future projects.

< >

>

Many professionals in construction operate under assumptions that can inadvertently lead to costly mistakes. While the importance of reliable borehole and daylighting solutions is widely acknowledged, there are nuanced pitfalls that even experienced teams sometimes overlook. Let’s dig deeper into what most people get wrong about these critical site services and how to avoid common traps.

Why Overconfidence in Standard Techniques Can Backfire

One misconception is that traditional drilling and daylighting methods are sufficient for all projects. This can lead to ignoring advancements like innovative drilling techniques that dramatically improve accuracy and safety. Relying solely on outdated practices might seem cost-effective initially, but it often results in rework, delays, and safety hazards. For example, using a generic approach without site-specific assessment can cause utility strikes or structural failures. Recognizing when to upgrade your methods is crucial—consulting with experts who leverage the latest technology can save time and money.

Beware of the Hidden Risks in Utility Mapping

A common trap is underestimating the importance of precise utility mapping before borehole installation. Many assume that superficial surveys are enough, but studies show that utility strikes are a leading cause of project delays and safety incidents (source). Advanced utility mapping techniques like vacuum excavation can reveal underground utilities with high accuracy, preventing costly surprises. Skipping this step or relying on outdated data can be a costly mistake, especially in dense urban environments.

How to Recognize and Avoid the ‘One-Size-Fits-All’ Mindset

Another widespread myth is that one borehole or daylighting solution fits all projects. Each site has unique geological, environmental, and logistical factors. For instance, optimizing borehole strategies involves tailoring techniques to specific soil and rock conditions. Failing to adapt can lead to inefficiencies, increased costs, and compromised safety. Conducting thorough site assessments and consulting specialists ensures your approach is customized, relying on data-driven decisions rather than assumptions.

Are You Falling for the Myths About Cost and Speed?

Many believe that investing in advanced site services and technologies will significantly increase costs or delay projects. However, modern solutions like vacuum excavation and strategic borehole placement actually enhance efficiency, reduce site disruption, and ensure compliance. The initial investment often pays for itself through fewer delays and safer work environments. Remember, rushing or cutting corners to save money upfront can lead to exponential costs later.

In conclusion, the key to mastering borehole and daylighting solutions lies in understanding the nuances and avoiding these common misconceptions. Staying updated with the latest technology, conducting detailed site assessments, and customizing strategies are essential steps toward safer, more reliable construction projects. Have you ever fallen into this trap? Let me know in the comments.

How do I keep my site services running smoothly over time?

Maintaining optimal performance in borehole and daylighting projects isn’t just about initial setup; it’s an ongoing process that demands the right tools and methods. From advanced equipment to software, I rely on specific solutions that enhance safety, accuracy, and efficiency throughout the project lifecycle. One tool I swear by is vacuum excavation—it allows me to perform precise subsurface assessments without risking utility strikes or causing unnecessary site disruption. I’ve seen firsthand how using vacuum excavation improves accuracy and safety, saving both time and money in the long run.

For project management and planning, I highly recommend leveraging specialized software that integrates data from site assessments, utility maps, and drilling plans. These tools help me visualize potential issues before they happen and ensure all team members are aligned. As technology progresses, I predict that AI-driven analytics and real-time monitoring systems will become standard, providing even deeper insights into site conditions and equipment performance.

When it comes to equipment maintenance, routine checks and calibration are essential. For borehole drilling, I use high-quality drill rigs with integrated diagnostics that alert me to potential issues before they escalate. Regular maintenance extends equipment lifespan and reduces unexpected breakdowns, keeping projects on schedule.

Additionally, investing in reliable communication tools ensures seamless coordination among field crews, engineers, and project managers. Clear communication is vital for adapting to unforeseen challenges and maintaining safety standards.

What strategies do I use to keep my tools effective over the years?

Beyond the hardware, I emphasize continuous training for my team. Staying updated on the latest techniques and safety protocols ensures everyone can operate tools confidently and correctly. I also review past project data to identify patterns or recurring issues, allowing me to refine our processes proactively.

Finally, building strong relationships with trusted suppliers and service providers ensures quick access to spare parts, technical support, and up-to-date equipment. This network is crucial for maintaining high standards and responding swiftly to any tool-related issues.

If you want to boost your project’s reliability, start by integrating vacuum excavation into your site assessments—it’s a game-changer for accurate, safe, and efficient site prep. Don’t forget to also explore advanced planning software and routine maintenance routines to keep your equipment in top shape. Remember, the key to long-term success is continuous improvement and investment in the right tools.

The Hardest Lesson I Learned About Site Safety and Precision

One of the most valuable lessons I learned was the importance of never assuming that standard borehole techniques will suit every project. Each site has its own quirks, and relying on outdated methods can lead to costly mistakes like utility strikes or structural issues. It took a few setbacks to realize that investing in innovative solutions and tailored assessments pays off in safety and efficiency.

My Essential Toolkit for Reliable Site Services

Over the years, I’ve come to trust tools like vacuum excavation for precise underground utility mapping. This technology drastically reduces surprises during drilling and ensures safety. I also rely on advanced planning software that integrates data from site assessments, helping me visualize potential issues before they happen. Regular equipment maintenance and ongoing team training keep our workflows smooth and our safety standards high.

Embrace Action, Not Fear—Shape the Future of Construction Safety

In 2024, the key to safer and more reliable construction lies in proactive planning, adopting innovative technologies, and customizing strategies to each site’s unique needs. By doing so, you not only protect your team but also accelerate project timelines and reduce costs. The future of construction safety is in your hands—are you ready to lead the change?

What’s the biggest challenge you’ve faced with site safety or borehole planning? Share your experience below and let’s learn together!