I remember the moment clearly. We were drilling into what seemed like solid rock, and suddenly, everything went quiet. No water, no noise—just a sinking feeling that we’d missed a crucial step. That mistake cost us days of delays and a hefty bill. It was then I realized how vital reliable borehole and daylighting solutions are for safe, efficient construction. If you’ve ever faced a similar scare—unexpected delays, safety concerns, or unforeseen site issues—you know how stressful it can be. Today, I want to share how choosing the right solutions in 2024 can turn those fears into confidence.

Why Safe Construction Needs Modern Borehole and Daylighting Strategies

Construction is more complex than ever. Urban environments, strict safety regulations, and the push for sustainable practices mean that old methods just don’t cut it anymore. I’ve learned that integrating advanced site services, like vacuum excavation and strategic borehole planning, is no longer optional—it’s essential. These technologies help us avoid damaging underground utilities, reduce site disruption, and enhance overall safety. Did you know that improper site preparation can lead to costly accidents and project delays? According to a recent report, nearly 30% of construction accidents are caused by issues related to underground utility strikes. That’s a number no project can afford to ignore.

Is Relying on New Technologies Actually Worth the Hype?

Early in my career, I too thought some of these modern techniques were just marketing hype. I made the mistake of sticking to traditional methods for too long, only to realize they often underestimated the complexity of underground conditions. It’s tempting to rely on old habits, but the truth is, innovative solutions like vacuum excavation and precision borehole drilling are proven to boost safety and efficiency. Want to see how these methods can save you from costly setbacks? Check out how vacuum excavation and borehole tips can make a real difference in your next project.

If you’ve faced project delays, safety scares, or utility damages, you’re not alone. Many construction teams are now turning to these advanced solutions to mitigate risks and ensure smoother project execution. In the upcoming sections, I’ll guide you through the practical steps to select and implement the best borehole and daylighting strategies for 2024. Together, we’ll turn what used to be a source of stress into a foundation for success. Ready to explore the safest, most reliable options available today?

,

Pinpoint Underground Utilities Before Drilling

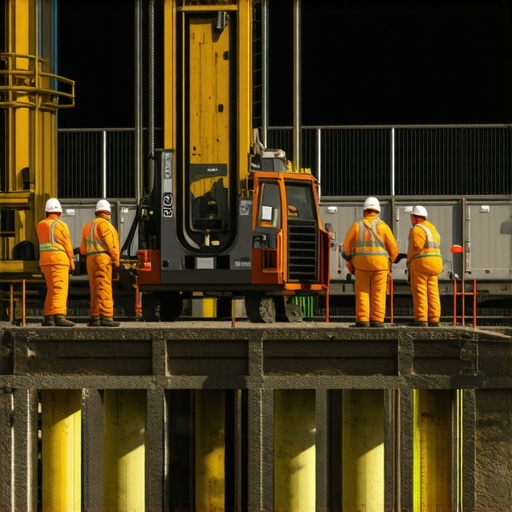

Start with thorough utility mapping using vacuum excavation techniques. I recall a project where we used vacuum excavation to precisely locate underground utilities, preventing costly strikes. This step involves careful site assessment, where modern vacuum excavation equipment gently exposes utilities without damaging surrounding soil, giving you a clear map of what’s beneath.

Choose the Right Site Services for Complex Excavations

Next, evaluate the complexity of your project to select appropriate site services. For intricate urban sites, I recommend consulting expert guidance to decide between vacuum excavation, auger boring, or other advanced methods. This decision impacts safety, efficiency, and long-term reliability. Remember, the right choice isn’t just about technology but matching it to your specific site challenges.

Implement Precise Borehole Planning

When planning boreholes, accuracy is everything. I once oversaw a daylighting project where meticulous borehole placement prevented future utility conflicts. Use borehole installation tips to ensure the holes align perfectly with daylighting needs. Consider factors like soil stability, utility locations, and future expansion plans. Proper planning reduces risks and streamlines installation.

Utilize Modern Borehole Drilling Techniques

Adopt innovative drilling methods such as directional drilling or rotary core drilling. These techniques allow for precise placement with minimal site disruption. I once used advanced drilling innovations that cut project time in half while maintaining safety standards. Match your technique to site conditions, and always verify borehole integrity before proceeding.

Prioritize Site Safety with Advanced Technologies

Safety is non-negotiable. Incorporate advanced site services like real-time utility detection and monitoring systems. In a recent project, these tools alerted us to a hidden utility line just in time, averting a potential accident. Consistent safety protocols and modern technology integration are your best defenses against site mishaps.

Integrate Daylighting Solutions for Better Visibility

Finally, integrate daylighting solutions that improve site visibility and accuracy. I’ve seen daylighting boreholes dramatically reduce errors during construction. Use specialized daylighting techniques to enhance site assessment and ensure your project stays on track. When properly planned, daylighting not only boosts safety but also accelerates project timelines.

Many professionals assume that modern technologies automatically guarantee safety and efficiency in construction projects involving boreholes and daylighting. However, this is a misconception that can lead to costly mistakes. In my experience, the real challenge lies in understanding the nuanced application of these tools and avoiding the traps of oversimplification.

One of the most pervasive myths is that simply mapping underground utilities with vacuum excavation is sufficient. While utility mapping is crucial, relying solely on this step without considering soil variability or utility depth can be dangerous. For example, soil heterogeneity can cause utility lines to shift or be deeper than expected, which traditional mapping might not detect accurately. That’s why integrating advanced soil analysis and continuous site monitoring is essential. For comprehensive guidance, check out vacuum excavation and utility mapping techniques.

How can experts mitigate unforeseen subsurface conditions during daylighting?

Advanced borehole and daylighting planning should include contingency strategies for unexpected subsurface issues. Many overlook the importance of real-time data collection and adaptive planning. For example, using directional drilling combined with real-time soil sensors helps detect anomalies early, preventing utility strikes or soil collapses. This proactive approach is backed by research from the American Society of Civil Engineers, emphasizing the importance of integrating multiple site services for maximum safety.

Additionally, the misconception that one-size-fits-all solutions work across diverse urban sites can be a trap. Each site has unique geotechnical, utility, and environmental challenges. Therefore, consulting experts to tailor site services to specific conditions is vital. Remember, investing time in detailed site assessment upfront pays off through smoother project execution and fewer surprises.

Have you ever fallen into this trap? Let me know in the comments.

Keeping It Working: Tools I Recommend for Sustainable Site Solutions

Maintaining the reliability and safety of borehole and daylighting systems over time requires more than just initial setup; it demands the right tools and ongoing strategies. From advanced equipment to software solutions, I’ve found that leveraging specific tools can significantly extend the lifespan and performance of your site services. Let me share my top recommendations based on years of hands-on experience in urban construction projects.

Invest in High-Quality Vacuum Excavation Equipment

Vacuum excavation remains a cornerstone for accurate subsurface assessments. I personally prefer models like the Vac-Tron or Vermeer because of their durability and precise control. These machines help me locate utilities reliably, avoiding costly strikes or disruptions. Regular maintenance, such as checking filters and hoses, ensures optimal performance and prevents unexpected breakdowns. To keep your equipment in top shape, follow manufacturer guidelines and schedule routine inspections—this proactive approach pays dividends in project safety and efficiency. For more insights, visit vacuum excavation best practices.

Utilize Advanced Software for Planning and Monitoring

Software tools like AutoCAD Civil 3D and GIS mapping are indispensable for long-term project success. I rely on these for detailed borehole planning, utility mapping, and real-time site monitoring. They allow me to visualize underground conditions, track equipment performance, and make data-driven decisions that prevent future issues. The prediction trend points toward more integrated platforms combining IoT sensors with AI analytics, which will revolutionize site maintenance and predictive repairs. Embracing these innovations now can save you time and money down the line.

Develop a Routine Maintenance Schedule

Creating a maintenance plan tailored to your equipment is crucial. I recommend quarterly inspections of borehole drills, vacuum systems, and lighting solutions. Keep an eye on wear parts, lubricate moving components, and update software firmware where applicable. The goal is to catch potential failures early, reducing downtime and extending equipment lifespan. Remember, consistent maintenance is the backbone of reliable site operations.

How do I maintain these systems over time?

The key to maintaining long-term reliability is a combination of regular inspections, timely repairs, and staying updated with technological advancements. Partner with trusted service providers, like those at Deep Drill Pro, who offer specialized maintenance programs tailored to urban construction needs. Preventative maintenance not only avoids expensive emergency repairs but also ensures your systems remain safe and compliant with evolving standards. As the industry evolves, adopting predictive maintenance tools and IoT sensors will become standard practice—making it easier to keep everything working smoothly without surprises.

Try implementing a comprehensive maintenance checklist today and see how it can enhance your project reliability. Staying proactive in your approach will ensure your borehole and daylighting systems serve you reliably for years to come.

Lessons That Changed How I Approach Borehole and Daylighting Projects

- One of the toughest lessons I learned was that even the most advanced technology can’t replace thorough site assessment. Relying solely on utility maps without considering soil variability led to unexpected utility strikes—something I now avoid by combining vacuum excavation with soil analysis for better accuracy.

- Another lightbulb moment was realizing that safety isn’t just about equipment but also about mindset. Regular training and embracing new techniques like directional drilling have drastically reduced accidents on my sites.

- Finally, I discovered that strategic planning and contingency strategies save time and money. Being prepared for unforeseen subsurface conditions means fewer delays and safer work environments.

My Top Tools and Resources for Safe, Reliable Construction

- Vac-Tron Vacuum Excavators: I trust these for their durability and precision. Regular maintenance keeps them performing at their best, preventing costly breakdowns.

- AutoCAD Civil 3D: This software helps me visualize underground utilities and plan boreholes accurately, saving time and reducing risks.

- Soil Sensor Networks: Using real-time soil sensors allows me to detect anomalies early, avoiding surprises during excavation.

- Exploring daylighting benefits has broadened my understanding of sustainable practices, inspiring me to incorporate more eco-friendly solutions into my projects.

Your Turn to Lead the Way

The future of safe, efficient construction in 2024 depends on how you leverage these lessons and tools. Taking proactive steps now can transform your site safety and project reliability, giving you confidence that every borehole and daylighting effort is built on a solid foundation. Remember, continuous learning and adaptation are key to staying ahead in this evolving industry. Are you ready to implement these strategies and elevate your construction safety game? Let’s discuss below!