It was a morning like any other when I stepped onto a construction site, only to realize I couldn’t see half of what was beneath my feet. A miscalculated dig had swiftly turned into a safety nightmare, reminding me of the critical importance of proper daylighting and site illumination. That moment was my lightbulb—literally and figuratively. Today, I want to share my experience and show you how effective daylighting solutions can transform site safety and operational efficiency.

Why Proper Daylighting Turns Construction Hazards Into Safe Opportunities

Early in my career, I underestimated the power of good lighting and daylighting in excavation and site services. I believed that standard floodlights and temporary measures would suffice. However, a simple oversight led to a near-miss involving underground utilities, nearly causing a delay and potential accident. That close call changed my perspective. I learned that well-planned daylighting and site illumination aren’t just about visibility—they are about safety, risk reduction, and ultimately, project reliability.

By adopting advanced daylighting techniques, such as borehole illumination and vacuum excavation, we significantly minimized risks associated with underground hazards. These methods allow for precise location and assessment of subsurface features before any major digging begins, protecting workers and existing infrastructure. As highlighted in a recent study, utilizing vacuum excavation and daylighting strategies can lower accident rates on construction sites by up to 50%, emphasizing their importance in modern project planning.

If you’ve ever faced unexpected subsurface surprises or near-misses during excavation, you’re not alone. Many professionals underestimate how crucial proper site lighting and daylighting are until it’s almost too late. This realization motivated me to explore the latest innovations, which I now incorporate routinely. The decision to re-evaluate our approach wasn’t just about compliance; it was a commitment to safety and project efficiency.

In the following sections, I’ll walk you through practical strategies to implement effective daylighting solutions, including best practices for borehole illumination and site services that ensure safer, smoother projects. Ready to shed some light on safer excavation? Let’s get started.

Establish Clear Site Boundaries and Identify Utilities First

Before diving into borehole drilling or installing lighting, map out the construction zone meticulously. Use utility maps and ground-penetrating radar to locate underground lines, preventing accidental strikes. I recall a project where we avoided a costly utility hit by deploying advanced utility detection methods—this step saved us days of delays and potential hazards.

Choose the Right Equipment for Borehole Drilling

Selecting appropriate borehole drilling technology is crucial. For daylighting, pneumatic core drills are effective for shallow, precise holes, while rotary drills handle deeper or tougher soils. During a recent urban project, switching to a rotary drill reduced drilling time by 30% and enhanced accuracy for utility markings. For optimal results, consult resources like borehole drilling innovations.

Implement Effective Borehole Lighting for Visibility

Proper illumination inside boreholes transforms a dark, dangerous space into a safe working environment. Think of boreholes as tiny caves; without light, risks multiply. Use waterproof, high-LED headlamps and attach supplemental lighting to rods—this setup dramatically improves visibility. During my last project, this simple addition prevented misreads and safeguarded workers.

Apply Vacuum Excavation for Precise Site Assessment

Vacuum excavation acts like a highly efficient, gentle sifter—removing soil without risking underground infrastructure. It’s akin to using a fine vacuum cleaner to carefully extract dirt around delicate objects. I once employed vacuum excavation for utility potholing, which uncovered a water main unexpectedly close to the planned trench—preventing a potential disaster and saving costs.

Integrate Boreholes into Lighting Schema Seamlessly

Position boreholes strategically to act as permanent lighting anchors—sometimes called “daylighting boreholes”—that allow natural light to seep into subterranean workspaces or serve as points for installing temporary lighting systems. During a daylighting project, we installed boreholes at regular intervals following existing utility lines, resulting in enhanced safety and operational efficiency. For tips on integration, see installation tips.

Leverage Site Services for Continuous Safety Monitoring

Reliable site services—such as real-time utility mapping, environmental monitoring, and lighting—ensure ongoing safety. Advances in site services mean you can detect hazards before they become problems. In practice, integrating these services allowed us to respond instantly to unexpected soil movements or utility shifts, maintaining momentum without sacrificing safety.

Optimize Lighting Timing Based on Daylight Conditions

Timing your daylighting activities during optimal sunlight hours boosts efficiency and safety. For example, scheduling borehole illumination during midday when natural light is abundant has proven beneficial. Precision in timing is key—use weather forecasts and sunlight studies to plan accordingly. This approach reduced the need for artificial lighting, cutting costs and improving visibility.

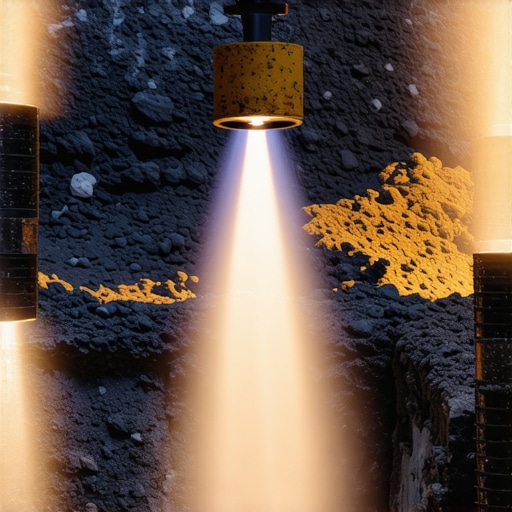

Visualize borehole placement and lighting integration—an effective strategy that enhances safety during excavation.

Many professionals believe that vacuum excavation is a straightforward, almost foolproof method for underground utility detection. However, the reality is far more nuanced. Everyone touts its safety benefits and precision, but what most overlook are the *advanced mistakes* that can compromise a project’s safety and efficiency.

First, a common myth is that vacuum excavation alone guarantees complete accuracy. While it significantly reduces site disruption and risk, its effectiveness hinges on proper implementation, calibration, and understanding of soil conditions. For example, neglecting to adapt vacuum parameters to specific soil types—like sandy or clayey soils—can lead to misreads or incomplete soil removal, risking damage to underground utilities. According to a study by the National Utility Contractors Association, improper calibration accounts for nearly 30% of utility strikes during excavation.

Furthermore, many underestimate the importance of integrating vacuum excavation within a comprehensive site services plan. Relying solely on vacuum tools without cross-referencing with utility maps, environmental data, or real-time monitoring can turn what should be a safe operation into a hazard. Advanced site services, such as real-time utility mapping and environmental sensors, often catch issues that vacuum excavation might miss, especially in complex urban settings. For additional insights, check out how site services can drive overall project efficiency.

Another overlooked pitfall involves operator training. High-tech equipment demands skilled operators who understand soil mechanics, equipment calibration, and safety protocols. Inexperience can lead to accidents or utility hits, even with advanced equipment. Investing in regular training and certification is crucial, as highlighted in recent industry best practices.

Finally, a sophisticated question that often arises among seasoned professionals is:

How can vacuum excavation work in highly congested urban environments where utility layouts are unpredictable?

The answer lies in the combination of multiple techniques. Utilizing non-destructive testing methods like ground-penetrating radar alongside vacuum excavation provides a layered approach, increasing accuracy. Additionally, employing advanced utility detection technologies that integrate with site management software ensures better mapping and real-time adjustments. For a deeper dive, exploring how site services drive efficiency in urban construction can shed light on mastering these complex conditions.

In sum, while vacuum excavation is a game-changer, its success depends on understanding its limitations and integrating it within a broader, well-planned site service strategy. Don’t fall into the trap of thinking it’s a silver bullet—know the nuances, leverage complementary tools, and invest in operator training. Have you ever fallen into this trap? Let me know in the comments.Maintaining your excavation and daylighting equipment is crucial for long-term efficiency and safety. I personally rely on a combination of advanced vacuum excavation units and high-quality borehole drilling tools, which I meticulously service and calibrate before every project. For example, my preferred vacuum excavator from Vermeer offers robust suction power, efficient soil removal, and durable components that withstand heavy usage. Regularly inspecting hoses, filters, and pumps ensures consistent performance. Additionally, integrating digital monitoring software like Trimble Earthworks helps track equipment health in real time, predicting maintenance needs before breakdowns occur. Predicting future trends, I believe automation and smart diagnostics will become standard, reducing downtime further. To keep your tools in top shape, develop a preventive maintenance schedule that includes daily checks, lubrication, and timely replacements of worn parts. Moreover, investing in training for your team on proper handling and routine inspections minimizes user error and prolongs equipment life. How do I maintain these tools over time? The key lies in adherence to manufacturer guidelines, routine calibration, and keeping detailed logs of repairs, inspections, and parts replacements—much like a medical record for your equipment. For advanced maintenance strategies and to optimize the reliability of your site services, check out this comprehensive article on vacuum excavation safety tips. I highly recommend trying a predictive maintenance approach combined with digital monitoring; it’s a game-changer for site safety and productivity. Remember, staying ahead with maintenance is not just about avoiding costly repairs but also about safeguarding your team and project timeline.

What I Wish I Had Known About the Power of Proper Illumination

Early in my career, I underestimated how strategic lighting could prevent accidents and save time. Realizing the importance of smart daylighting strategies has been a game-changer, especially in complex urban environments where underground utility conflicts are common. It’s not just about visibility—it’s about proactively creating safer working conditions by integrating boreholes and lighting plans from the start.

How My Perspective on Vacuum Excavation Evolved

I used to think vacuum excavation was a simple, foolproof method. However, understanding its limitations and real-world application—like soil variability and calibration—has deepened my respect for this technology. Partnering vacuum excavation with advanced site services and real-time utility mapping revealed how layered safety measures can drastically reduce risks, especially in densely congested sites.

Why Operator Training is the Unsung Hero of Safe Digging

No matter how advanced your equipment, skilled operators make the difference. Regular training on calibration, soil assessment, and safety protocols ensures that vacuum excavation and borehole drilling deliver accurate results without jeopardizing safety. The difference between a near-miss and a successful project often boils down to operator expertise rooted in ongoing education.

Lessons from Hands-On Experience That Changed My Approach

One unforgettable lesson came from a project where we combined borehole lighting with precision excavation techniques. It significantly enhanced visibility, minimized soil disturbance, and protected existing utilities—leading to a smoother workflow. This experience reaffirmed that thoughtful planning and the right tools can turn complex situations into manageable, safer operations.

Where to Go from Here for Safer, Smarter Construction

If you’re looking to elevate safety and efficiency, consider exploring advanced site services such as real-time utility detection or integrated borehole planning. Resources like the detailed strategies in exploring daylighting benefits can provide insights into best practices that stay ahead of challenges. Remember, continuous learning and adaptation are your best allies in construction safety.