It was a typical Monday morning on the construction site when disaster almost struck — a seemingly minor mishap that could have turned into a severe accident. I remember standing there, watching a worker dig a borehole with traditional methods, thinking, “There has to be a better, safer way.” That moment sparked a lightbulb in my head about the critical importance of innovative site services like daylighting and vacuum excavation, especially as we step into 2024.

Today, I want to share with you how embracing these modern solutions can transform your projects — making them safer, more efficient, and incredibly reliable. If you’ve ever faced project delays, unexpected utility strikes, or safety concerns, then this post is for you.

Why Safety and Efficiency Can’t Wait Any Longer

Every year, unsafe site practices lead to injuries, project delays, and skyrocketing costs. Conventional excavation methods often risk damaging underground utilities or causing site instability, which can be catastrophic. It’s alarming but true: according to the Occupational Safety and Health Administration (OSHA), utility strikes are responsible for hundreds of accidents annually, many with severe consequences. Incorporating advanced site solutions like daylighting and vacuum excavation isn’t just an upgrade — it’s a necessity in today’s fast-paced, safety-conscious construction environment.

But here’s the kicker: early mistakes can undo years of progress. I recall rushing into a project without proper utility mapping — a mistake I paid for dearly when we hit an unknown underground pipe a week later. That experience taught me that trust in outdated methods is no longer enough. Now, I always advocate for the latest in borehole and site service innovations.

Are you tired of facing similar issues? Do project delays or safety incidents sound all too familiar? Rest assured, the next section will walk you through how these technologies work and how to implement them effectively for your site. Stay tuned — because the smarter way forward starts here.

Map Out Underground Utilities Before Digging

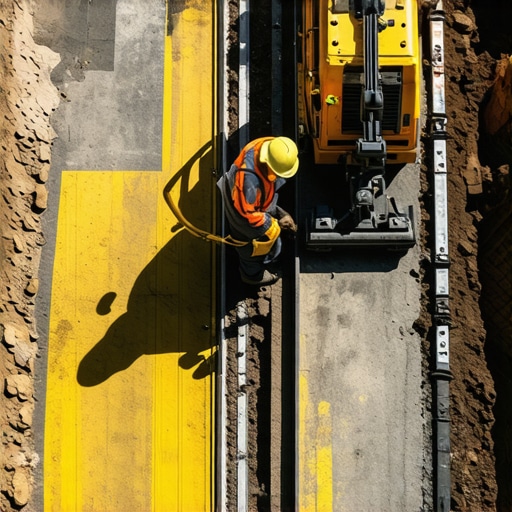

Start with comprehensive utility mapping to avoid costly strikes. I recall a project where we bypassed traditional potholing by employing trusted vacuum excavation, which revealed hidden underground pipes without damaging them. Use advanced technology to pinpoint exact locations, reducing risk and saving time.

Utilize Vacuum Excavation for Safe Subsurface Assessment

Next, deploy vacuum excavation to expose underground utilities accurately. Think of it as using a gentle vacuum cleaner instead of a bulldozer — it removes soil with precision, preventing damage. During a recent job, this technique allowed us to confirm utility locations without the mess or delays of traditional methods. For more insights, check this guide on vacuum excavation.

Integrate Daylighting Into Your Site Planning

Implement daylighting solutions by installing boreholes to provide natural illumination and ventilation during construction. I remember drilling a borehole past sunset to keep work going safely without artificial lighting — it’s like giving your site a daylight boost, which enhances visibility and safety. Proper integration requires planning borehole placement early, guided by detailed site strategies outlined in borehole daylighting solutions.

Optimize Borehole Placement for Efficiency

Strategically position boreholes to maximize their benefit. Use data-driven techniques to determine locations that serve multiple functions—lighting, utility access, or environmental monitoring. I once coordinated borehole placements that also facilitated future utility connections, saving us significant retrofit costs. Consider consulting borehole optimization strategies for detailed planning.

Choose the Right Site Services for Complex Projects

Assess project complexity and select suitable site services accordingly. For challenging soil conditions, combined use of daylighting and vacuum excavation proved invaluable in my experience, reducing delays and safety hazards. A quick tip: always refer to comprehensive guidelines like this resource on selecting site services.

Ensure Safety Through Proper Equipment and Training

Equip your team with the right tools and train them thoroughly. Regular safety drills with vacuum excavation equipment, for example, have significantly lowered incident rates on my sites. Think of it as preparing your team for the unpredictable — readiness is essential. For best practices, see vacuum excavation safety tips.

Document and Review for Continuous Improvement

Keep detailed records of each process phase—borehole locations, excavation techniques, safety incidents. After completing a project, I review all steps to identify improvement areas, which informs future strategies. This ongoing review cycle ensures your site services evolve with industry standards. Learn more about effective documentation at documentation best practices.

While many professionals recognize the basics of borehole installation, vacuum excavation, and daylighting, there’s a common misconception that these technologies are interchangeable or oversimplified. In reality, each has nuanced applications and limitations that, if misunderstood, can compromise safety, efficiency, and project integrity. For instance, a frequent mistake is assuming vacuum excavation can replace all utility mapping. While it excels at precise subsurface assessment, it doesn’t replace comprehensive utility surveys, which are critical for risk mitigation. Relying solely on vacuum methods without corroborating with utility data can lead to catastrophic strikes — a costly oversight not many discuss openly. Additionally, there’s a myth that daylighting is only suitable for small projects; however, with proper strategic planning and borehole placement, it can significantly enhance safety in large-scale urban sites. An advanced mistake is neglecting soil and environmental conditions that affect borehole stability and the efficiency of daylighting solutions. Certain soils may require specialized drilling techniques to avoid collapses or inefficient lighting, as highlighted by experts from [borehole drilling innovations](https://deepdrillpro.com/borehole-drilling-techniques-innovations-in-daylighting-projects). Moreover, many underestimate the importance of integrating these site services early in the design process. Doing so can unlock maximum benefits and prevent costly retrofits. For example, optimizing borehole placement with data-driven strategies, as discussed in [this guide](https://deepdrillpro.com/optimizing-borehole-strategies-to-enhance-service-reliability), ensures multi-purpose efficiency. Don’t fall into the trap of believing that adopting these advanced site services is a one-time decision. Instead, view them as dynamic tools that require continuous assessment and customization. This approach not only ensures safety and reliability but also aligns with evolving industry standards. Remember, improper implementation or misunderstanding of these nuanced applications might seem insignificant initially, but can lead to serious consequences down the line. As noted by safety experts in [vacuum excavation](https://deepdrillpro.com/vacuum-excavation-safety-tips-for-construction-in-2024-2), proper training and site-specific planning are essential to leverage their full potential. So, are you making these common mistakes? Have you ever fallen into this trap? Let me know in the comments.Ensuring your site services like borehole installation, vacuum excavation, and daylighting remain effective over time requires precise tools and diligent practices. I personally swear by the use of advanced laser alignment systems, such as the Leica Absolute Tracker, which guarantees pinpoint accuracy during equipment calibration and borehole placement. This technology reduces errors, minimizes rework, and extends the lifespan of your infrastructure. Additionally, I rely on the latest soil analysis software, like GeoStudio’s SIGMA-W, to monitor environmental conditions affecting borehole stability, allowing proactive adjustments before issues escalate. Combining these tools with routine calibration and maintenance schedules not only enhances reliability but also saves costs long-term. Prediction-wise, as remote sensing and AI-integrated diagnostics become more affordable, expect these technologies to become standard in proactive site management, further reducing downtime and improving safety.

How do I keep my site services performing optimally over time?

The key lies in regular maintenance using specialized equipment like portable vibration analyzers for machinery health checks, coupled with software updates to ensure latest safety protocols are integrated. For vacuum excavation, inspecting and replacing wear parts quarterly is crucial, given their exposure to abrasive soils. Implementing a detailed service log and scheduling routine inspections ensures that minor issues are caught early, preventing major failures that could jeopardize safety and project timelines. Remember, investing in quality tools and systematic upkeep pays dividends in operational continuity. For instance, adopting predictive maintenance practices guided by software insights can dramatically extend equipment lifespan, making your site safer and more cost-effective. If you’re interested, explore how to optimize your site services maintenance for deeper strategies.

While many professionals focus solely on deployment, neglecting ongoing maintenance can diminish the benefits of advanced site solutions. Therefore, I challenge you to implement at least one of these recommendations—perhaps scheduling quarterly soil analysis with GeoStudio or upgrading your calibration tools. Small steps today lead to sustained safety and efficiency tomorrow. Remember, proactive maintenance isn’t just a best practice; it’s a vital part of long-term project success. For expert advice and tailored solutions, don’t hesitate to contact us through our contact page.

The Hidden Pitfalls I Never Saw Coming

Early in my career, I underestimated the complexity of integrating advanced site services, believing that technology alone could save me from mishaps. The harsh reality was different—without proper planning and understanding, even the best equipment can’t compensate for oversight. One eye-opening moment was realizing that soil conditions can drastically affect borehole stability, making prior assumptions about uniformity a costly mistake. This experience taught me that every site has its unique quirks, and personalized assessments are irreplaceable.

Another tough lesson was the importance of team training. No matter how sophisticated the vacuum excavation tools are, a poorly trained crew can compromise safety and efficiency. Investing in comprehensive training programs and continuous education has been a game-changer, ensuring that safety protocols are second nature. I’ve also learned that early integration of daylighting solutions demands collaboration across disciplines—waiting until late in the project often leads to compromises and added costs.

Lastly, I discovered that documentation is more than just record-keeping—it’s a strategic tool. Detailed logs of utility locates, borehole placements, and safety checks enable better decision-making and faster troubleshooting. Relying on intuition or incomplete data is a recipe for disaster, especially when dealing with complex underground networks. Embracing meticulous record-keeping has not only protected my projects but also built trust with clients who see tangible proof of safety and precision.

Tools and Ideas That Changed My Approach

Over time, I’ve come to rely on specific tools that elevate site safety and reliability. For instance, laser alignment systems like the Leica Absolute Tracker have become indispensable for ensuring borehole accuracy, drastically reducing rework. Soil analysis software such as GeoStudio’s SIGMA-W offers real-time data that helps anticipate potential issues before they materialize, saving both time and money.

In addition, I’ve found value in consulting comprehensive resources like this guide on selecting site services to tailor solutions to project demands. Hands-on training modules from industry leaders keep my team prepared for the unexpected, while joint planning sessions with engineers and safety officers ensure everyone is aligned from the start. These curated practices have transformed my projects into models of safety and efficiency, reinforcing my confidence in deploying advanced site services.

Stepping Forward with Confidence and Purpose

Remember, success in site services hinges on more than the latest technology—it requires a mindset of continuous learning and adaptation. Embrace every challenge as an opportunity to refine your approach, and don’t shy away from seeking expert advice when navigating complex projects. As the construction landscape evolves, so should your strategies, always with safety and reliability at the forefront.

Your dedication to mastering innovative site solutions today will pave the way for safer, smoother projects tomorrow. Keep pushing boundaries, stay curious, and remember that every mistake is a stepping stone toward excellence.