I remember the moment clearly. We were midway through a complex site project when suddenly, an underground utility line was hit—an oversight that caused hours of delay and a hefty repair bill. It was a stark wake-up call. I realized that without proper site services, especially in excavation and daylighting, we gamble with safety, efficiency, and ultimately, the project’s success. That experience taught me the importance of reliable, expert solutions designed for today’s construction challenges.

What Makes Site Services Essential in Today’s Construction Landscape

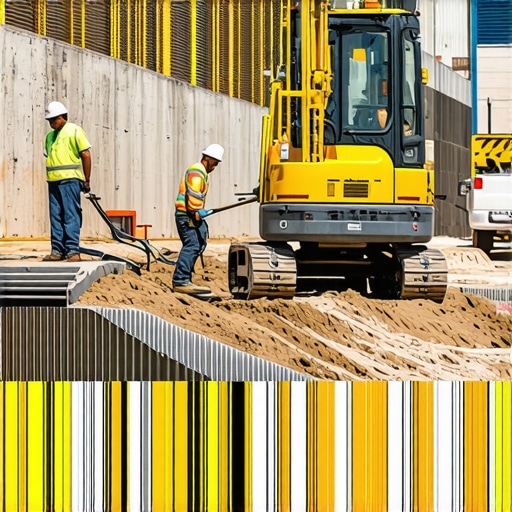

Construction projects are more intricate than ever. Urban environments are dense, underground utilities are numerous, and safety regulations have tightened. Without expert site services, particularly in safe excavation and daylighting, the risks multiply. Properly executed, these solutions help avoid costly surprises, reduce site disruption, and protect workers and infrastructure alike. When I started to dig deeper into these services, I was surprised to learn how much safer and more efficient projects become when using advanced techniques like vacuum excavation and precise borehole drilling. For an eye-opening overview, check out this resource on daylighting benefits.

Is Investing in Expert Site Services Really Worth It?

Early in my career, I made the mistake of cutting corners on site prep—thinking it was just an added expense. That was a costly lesson. It’s tempting to underestimate the value of expert solutions, but the truth is, cutting corners often leads to safety hazards, project delays, and increased costs. Reliable site services ensure precise work, reduce site disturbance, and keep everything on schedule. Trust me, the difference between a well-executed project and one plagued with issues often boils down to choosing the right partners. For guidance on selecting the best services, I recommend reviewing this detailed guide.

Prepare for Precise Site Mapping and Utility Detection

Start by conducting thorough underground utility mapping using advanced techniques like vacuum excavation, which minimizes disruption and provides accurate subsurface data. I remember a project where we used vacuum excavation to carefully expose utility lines before trenching; it saved us from costly damages and delays. This step is crucial for avoiding accidents and ensuring safety, especially in urban environments. For detailed insights, explore this resource on utility mapping.

Implement Expert Excavation Techniques for Accuracy

Choose the right excavation method based on soil type and site conditions. I once employed a combination of vacuum excavation and traditional methods when working on a complex site. Vacuum excavation allowed us to precisely locate and protect underground structures, while traditional methods handled the bulk removal. This hybrid approach increased accuracy and safety. Remember, employing modern vacuum excavation solutions is a game-changer for safe site prep.

Optimize Borehole Placement for Effective Daylighting

Proper borehole placement is vital for successful daylighting. I once had to plan boreholes around existing underground utilities, which required careful strategizing. Using borehole drilling innovations, we positioned boreholes to maximize daylighting while maintaining safety margins. Precise placement reduces site disruption and enhances structural visibility. For advanced techniques, review this guide on borehole drilling innovations.

Ensure Safety with Continuous Monitoring and Communication

Throughout the project, maintain real-time monitoring of excavation and daylighting activities. I learned this the hard way when a miscommunication led to accidentally striking a utility line. Implementing clear communication protocols and using site sensors improved safety and efficiency. Regular updates and safety checklists keep everyone aligned. For comprehensive safety strategies, visit this safety-focused resource.

Refine Your Process with Post-Excavation Verification

After excavation and daylighting, verify all utilities and structural elements before proceeding. I recall a project where post-excavation verification uncovered an unmarked utility, preventing future issues. Using nondestructive testing and precise surveying ensures everything is in order. This final check is essential for project reliability and safety. Explore utility mapping post-excavation techniques for best practices.

Many professionals in construction believe that cutting corners on site services, such as excavation and utility detection, is a cost-effective way to stay within budget. However, this misconception can lead to costly mistakes that outweigh any initial savings. In my experience, investing in expert solutions like vacuum excavation and precise borehole drilling significantly reduces risks, project delays, and safety hazards. For instance, relying solely on traditional excavation methods in complex urban environments often results in utility strikes that could have been avoided with advanced techniques. To understand the true benefits of these modern approaches, check out this resource on daylighting benefits.

What advanced site services do construction professionals often overlook or misunderstand?

A common oversight is underestimating the importance of continuous safety monitoring and proper post-excavation verification. Many think that once utilities are exposed, the job is done. But in reality, ongoing monitoring and detailed verification are vital for ensuring that no utility lines were missed or damaged during excavation, preventing future issues. Modern nondestructive testing and precise surveying techniques, discussed in utility mapping post-excavation, provide greater reliability and safety.

Another subtle but critical nuance is the strategic placement of boreholes for daylighting. Many assume that any borehole will do, but advanced strategies involve optimizing borehole locations to maximize daylighting efficiency while minimizing site disturbance. This requires detailed planning and innovative drilling techniques, which are often overlooked in favor of quick solutions. For a deeper dive, explore this guide on borehole drilling innovations.

Lastly, I want to highlight the myth that all site services are interchangeable. In reality, the choice of specific techniques and equipment—like vacuum excavation versus traditional methods—dramatically impacts safety, accuracy, and overall project success. Ensuring that your team understands these nuances can make the difference between a smooth project and a costly fiasco. For expert insights on selecting the right services, review this comprehensive guide.

Have you ever fallen into this trap? Let me know in the comments. Remember, understanding these hidden nuances helps you avoid costly mistakes and ensures safer, more efficient construction projects.

Keeping It Working: Essential Tools and Maintenance Strategies

Maintaining the integrity and efficiency of site services like vacuum excavation and borehole drilling isn’t a one-time task; it requires ongoing attention and the right tools. Over the years, I’ve found that investing in high-quality equipment and adhering to disciplined maintenance routines can significantly extend the lifespan of your tools, reduce downtime, and ensure safety on the job site.

One of my go-to pieces of equipment is a reliable vacuum excavator. I personally prefer models that come with automated self-cleaning features, such as the Vac-Con series, because they minimize manual cleaning and reduce the risk of cross-contamination. Regularly inspecting hoses, filters, and pumps is crucial—if any component shows signs of wear or clogging, replacing it immediately prevents larger failures down the line. For a deeper understanding of vacuum excavation maintenance, I recommend reviewing this detailed resource.

Similarly, borehole drilling equipment demands meticulous upkeep. I rely on precision drill bits made from tungsten carbide for longevity and accuracy. Keep the drill head lubricated, and routinely check alignment and calibration. Using software like DrillTrack helps me log maintenance schedules and monitor wear patterns, ensuring consistent performance. As technology advances, integrating IoT sensors into your machinery can provide real-time diagnostics, predictive maintenance, and reduce unexpected breakdowns.

How do I maintain site services over time?

The key is to develop a routine maintenance schedule tailored to your equipment’s usage and manufacturer’s recommendations. Regular lubrication, cleaning, and calibration are non-negotiable. Additionally, training your team to identify early signs of wear—such as unusual vibrations or decreased suction—can prevent costly repairs and delays. For example, I schedule quarterly inspections and keep spare parts on hand, like replacement hoses and filters, to minimize downtime.

Predictive maintenance is the future, and I believe that adopting IoT-enabled sensors and data analytics will become standard practice. These tools can alert you to issues before they cause failures, saving time and money. Staying ahead of the curve means regularly updating your equipment and training your team on new technologies.

Finally, don’t forget the importance of documentation. Maintaining detailed logs of repairs, replacements, and inspections helps identify recurring issues and plan for upgrades. For more insights on optimizing your site services, check this comprehensive guide.

Start implementing a proactive maintenance routine today and see how it transforms your project outcomes. Remember, well-maintained tools are the backbone of safe, efficient, and reliable site services.

The Hardest Lesson I Learned About Site Services

One of my most eye-opening experiences came when a seemingly small oversight in utility detection led to a project delay of weeks. This taught me that even minor miscalculations in site services can cascade into safety hazards and costly setbacks. Never underestimate the power of thorough utility mapping; a simple mistake can turn dangerous very fast. I learned to double-check every utility line, especially in dense urban areas, using advanced techniques like vacuum excavation, which significantly reduces the risk of utility strikes. For more insights, explore utility mapping for safe construction.

Three Myths About Excavation That Held Me Back

Initially, I believed that traditional excavation methods were sufficient for all projects. That myth was shattered when I saw how modern vacuum excavation drastically improves safety and precision. It became clear that investing in advanced site services isn’t just a luxury but a necessity for complex projects. Another misconception was that borehole placement doesn’t need meticulous planning—yet I found that strategic positioning enhances daylighting efficiency and reduces site disturbance. Lastly, I used to think safety monitoring was only necessary during active excavation, but continuous monitoring and communication are vital to prevent utility strikes and ensure team coordination. To understand these better, read this guide on choosing the right site services.

What Experts Won’t Tell You About Site Safety and Efficiency

The truth is, many construction professionals overlook the importance of post-excavation verification, which is crucial for confirming that all utilities are correctly identified and undamaged. Skipping this step can lead to future problems and safety risks. I also discovered that borehole placement is more art than science—optimized positioning based on innovative techniques can maximize daylighting while minimizing disruption. Employing modern tools such as IoT sensors for equipment maintenance and safety monitoring has transformed how I manage site services, saving time and preventing failures. For more on these innovations, check this resource on borehole strategies.

Reading this post really highlights how critical thorough site services are in today’s complex construction landscape. I’ve experienced firsthand how overlooked utility mapping and employing advanced excavation techniques like vacuum excavation can prevent costly delays and safety hazards. Especially in dense urban areas, even a minor utility strike can lead to major setbacks, so investing early in accurate utility detection and proper borehole placement seems like a no-brainer. I’m curious, how have others here integrated IoT sensors or real-time monitoring into their site safety protocols? I’ve started exploring these technologies to catch potential issues before they escalate, and I’d love to hear about experiences or recommendations on implementing such solutions effectively.

Reading this post brings back a recent experience I had during a commercial build in a dense urban area. We initially underestimated the importance of precise utility mapping, but after a utility line was accidentally struck—causing a significant delay—we realized how vital expert site services are in preventing these costly mistakes. We’ve since integrated real-time monitoring tools, like IoT sensors, into our site safety protocols, which have been game-changers. These sensors help us maintain constant oversight of excavation activities and detect anomalies early, significantly reducing risk. Has anyone else tried combining traditional site planning with advanced IoT technology? I believe that blending these approaches can really elevate safety standards and operational efficiency. Also, what are some best practices for training staff to interpret real-time data effectively on the field? Looking forward to hearing others’ insights on staying ahead through technology and experience.